Maintenance for M9B

Date:

Wednesday, September 12, 2012

Synopsis:

Patching Up Solenoid Gas Cooled Lead Flanges Leak

Equipment/Beam Line:

Description:

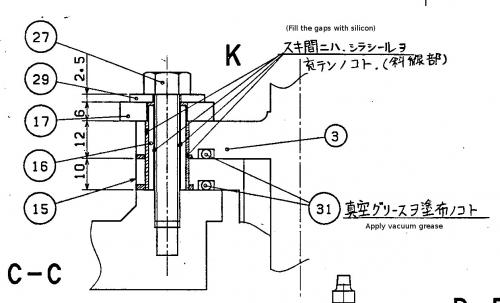

This leak is located on cooled gas lead flanges and is mostly on east side flange. It's due to old aged seal and is going to be patched up just for a short time! It will be fixed properly in the next long shut down.

Please note a LN2 cold trap was connected during all the following stages.

Helium leak check result beofre patching is (units are torr.lit/sec):

- pressure 2.5E-2

- background boefore zeroing: 3E-7

- after zeroing2E-9 to 3E-8

- helium leak rate: 3E-7 to 4E-6 depends on sprayed helium

One of the bolts were taken out and it was fully threaded with RTV on it. Technically, it's a poor practice to apply RTV as a sealant on fully threade bolts! So, these bolts(M8x40) are replaced with partially threaded ones.

Sep 27, 2012

East flange leak is fixed now temporarily at room temperature as described here:

- Each bolt was removed and replaced with a partially threaded one(SS316)

- Area was cleaned reasonably and carefully with solvents(Acetone and Ethanol)

- Some of the glass epoxy tubes came out, so they were easier to clean

- RTV-162 was applyed inside and outside of the tubes and around th bolts

- Original washers were used plus belleville washers

After all, leak result is as following:

- Pressure 2.4E-2

- background before zeroing: 0.8E-7

- background after zeroing: 3 to 7 E-9

- He leak rate: in 10-9 range (3 to 8 E-9)