Maintenance for BNQR Cryostat

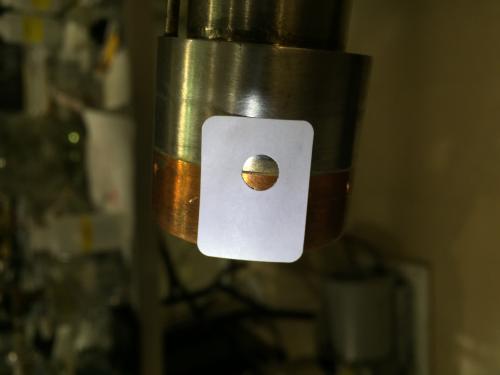

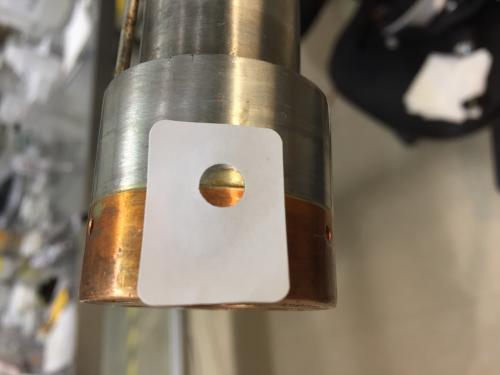

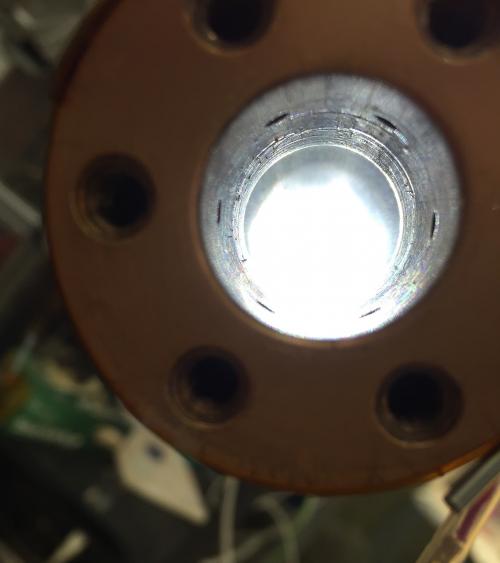

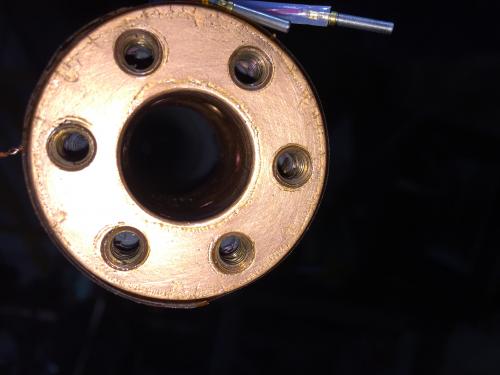

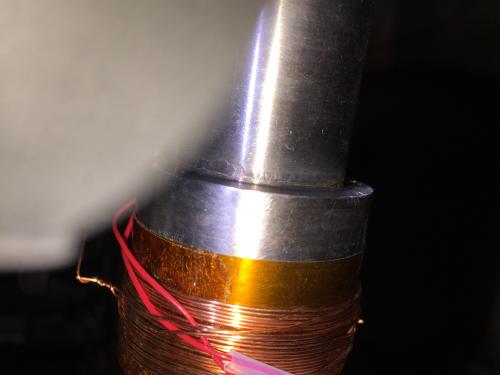

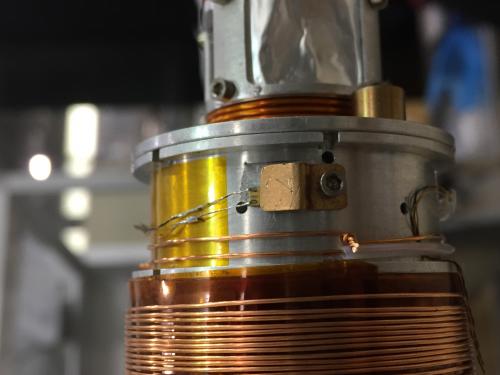

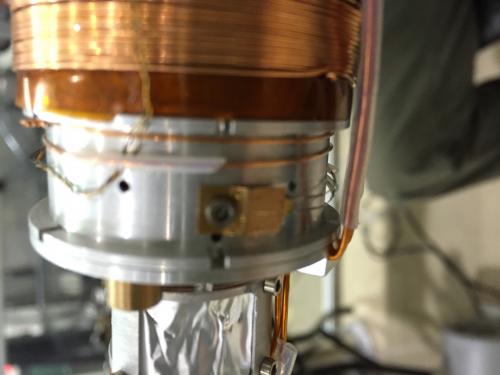

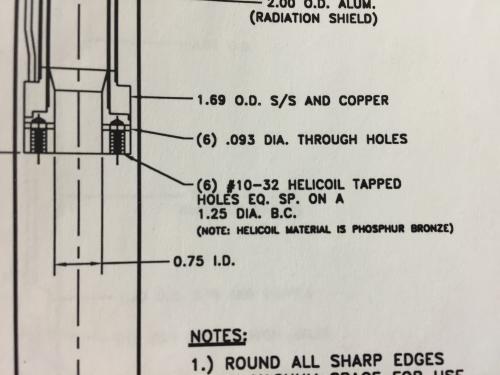

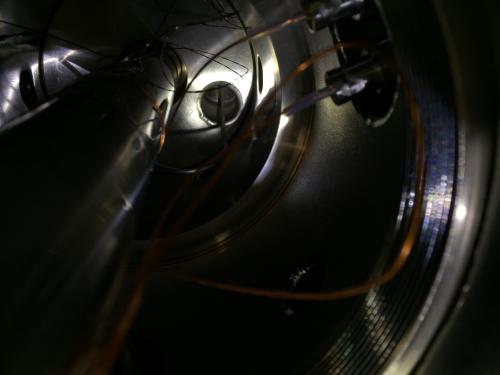

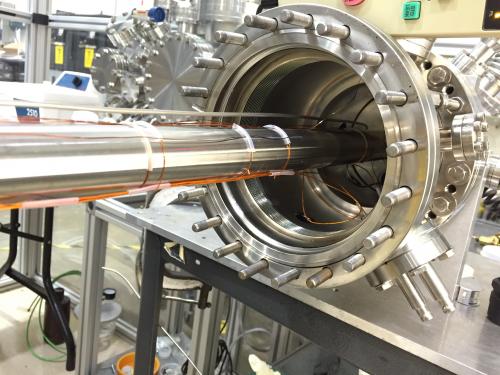

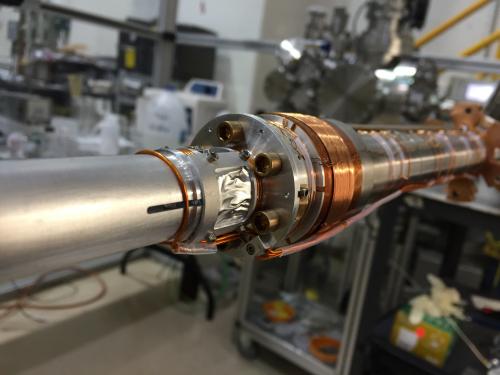

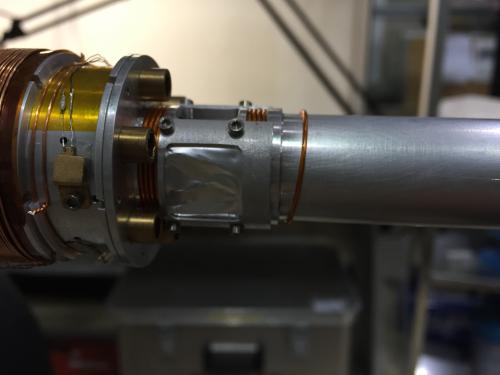

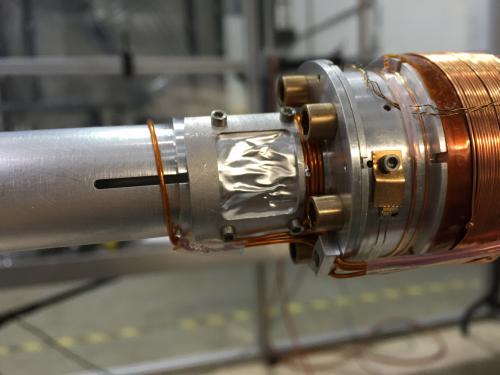

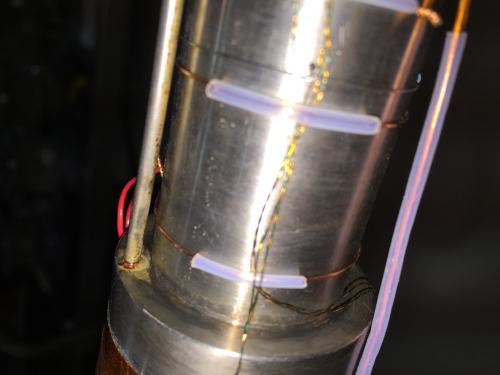

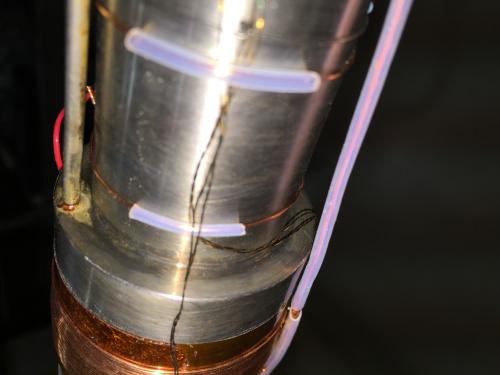

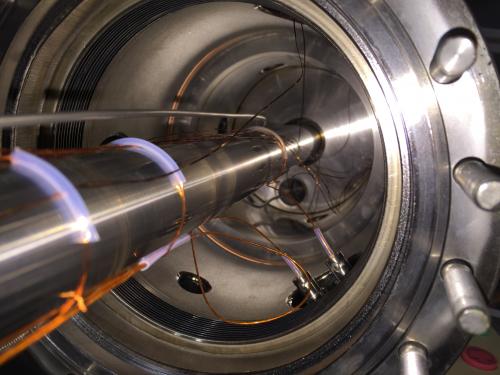

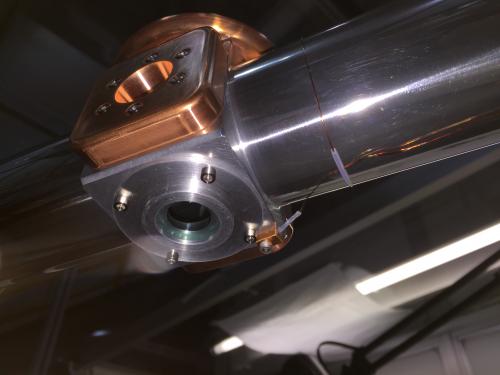

Cryostat was diagnosed with leaking helium into vacuum space. After removing cryostat from beamline and transferring to clean room, leak was found! looking into cryostat, it is around 3:00 o'clock on the outside joint of SS heat exchanger and copper block. background on the leak detector at 1mTorr is 1E-9 torr.lit/sec and leak rate is 4E-7 Torr.lit/Sec.

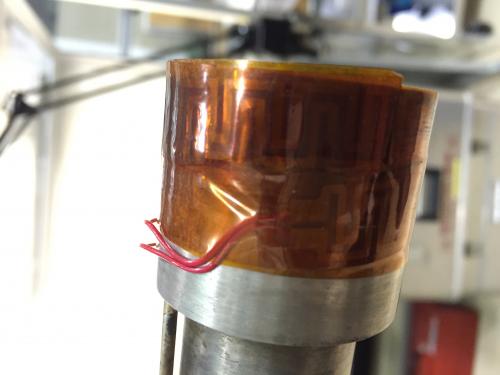

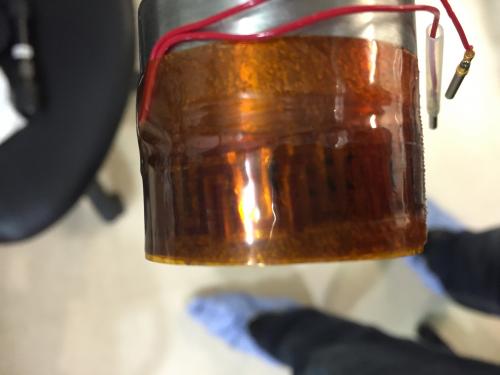

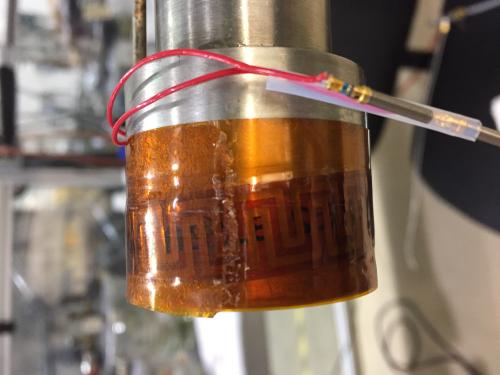

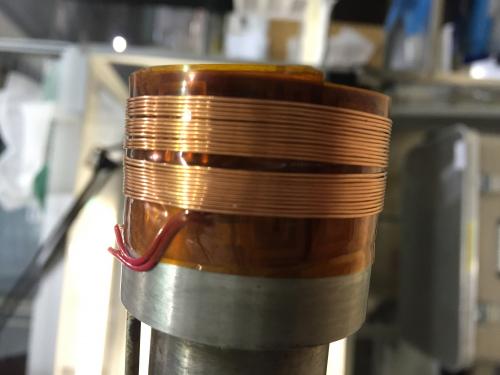

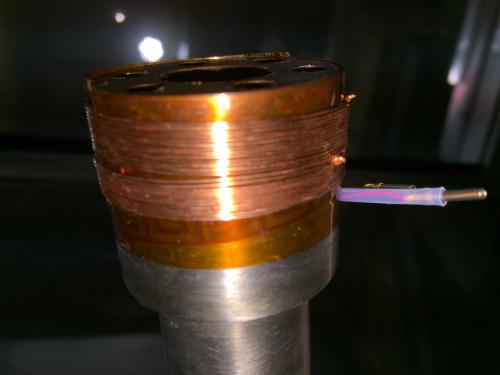

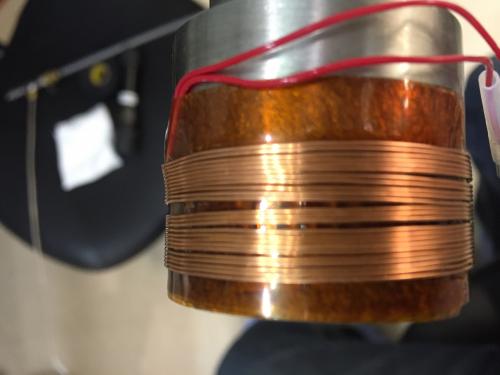

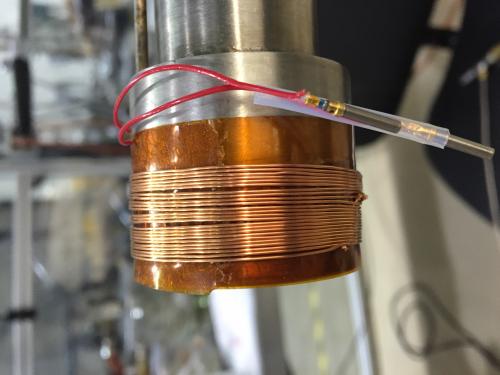

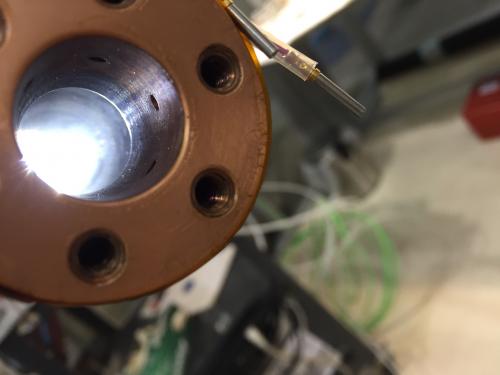

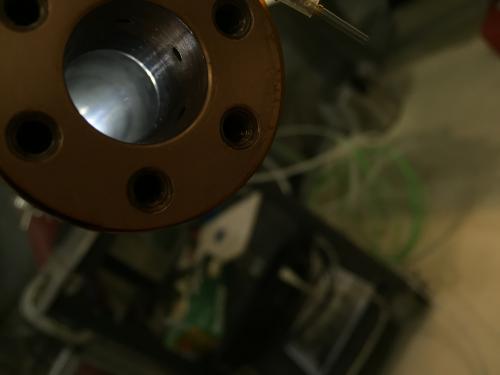

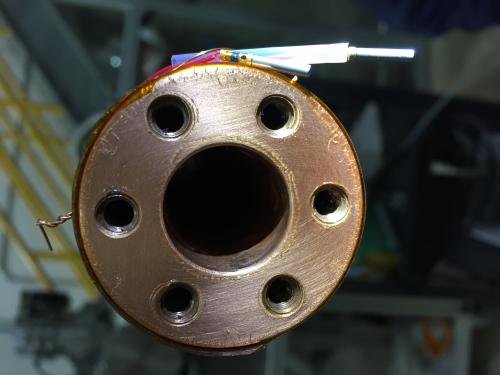

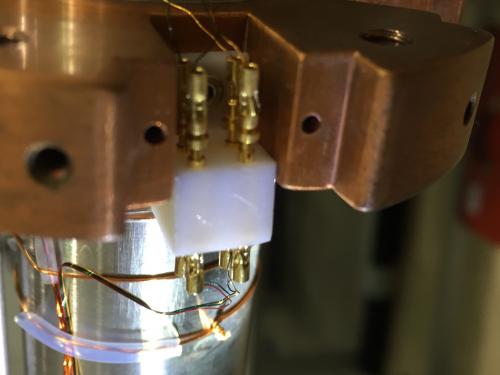

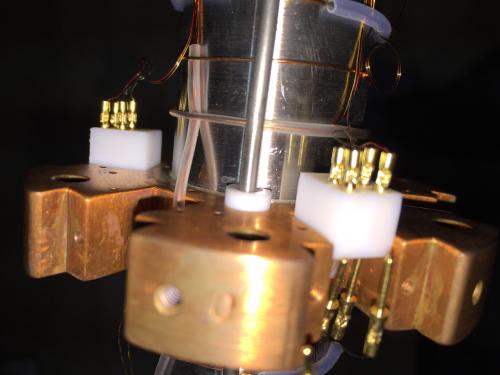

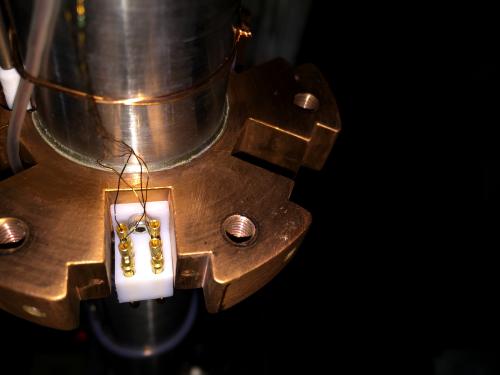

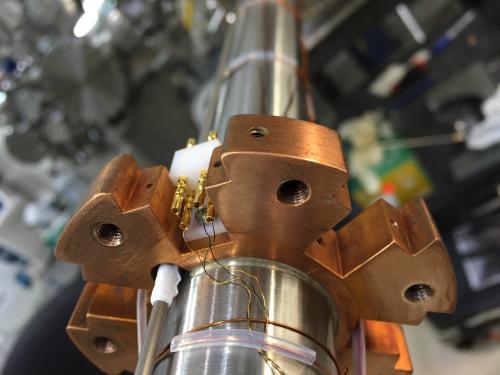

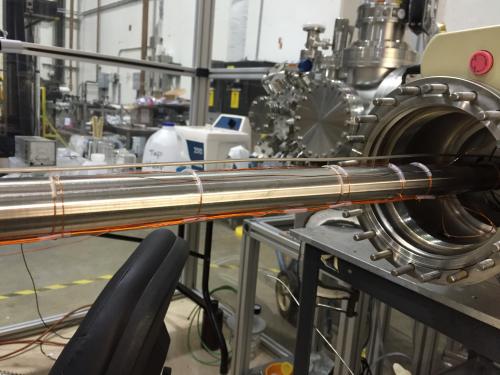

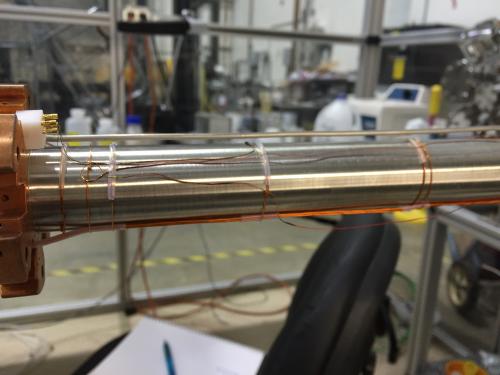

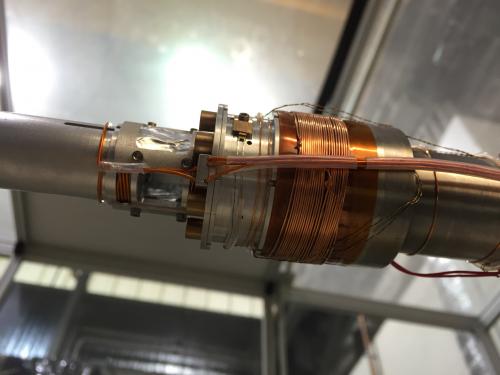

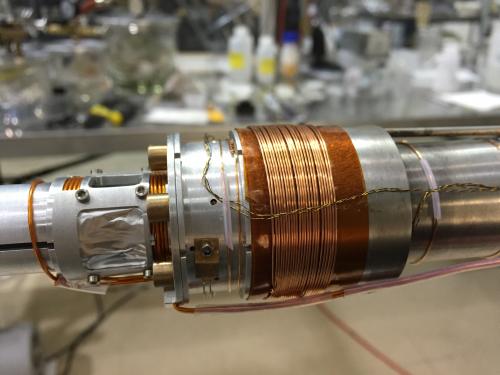

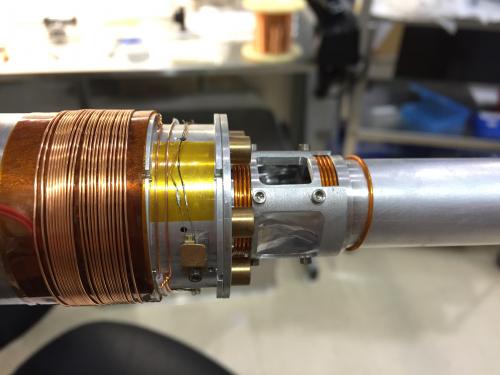

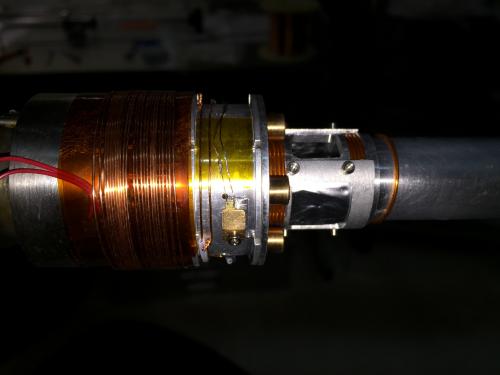

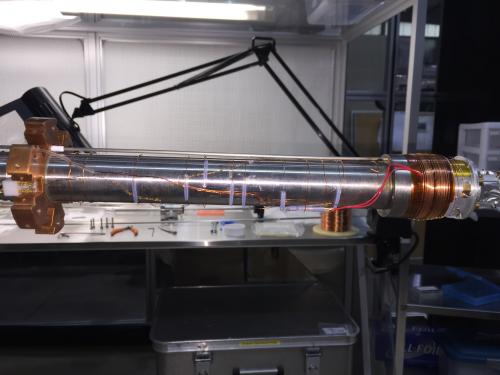

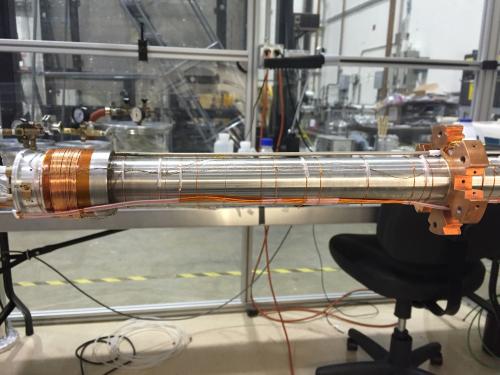

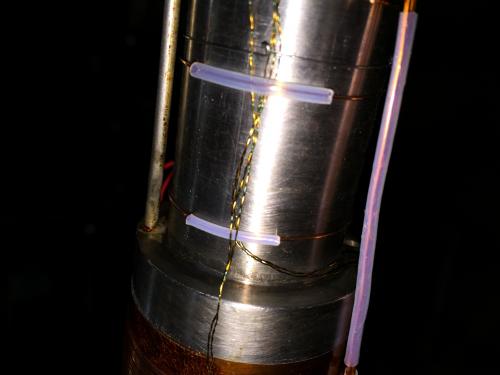

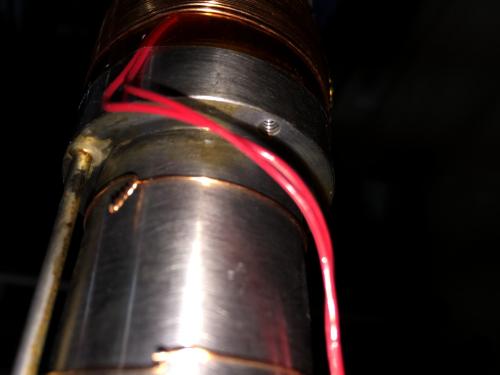

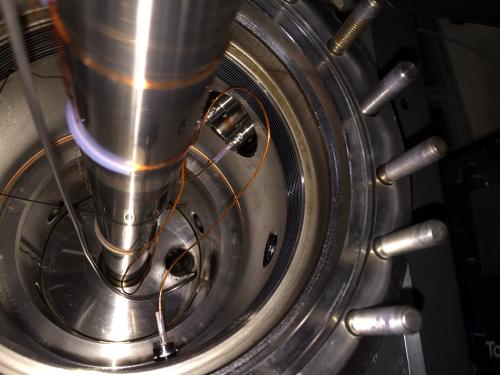

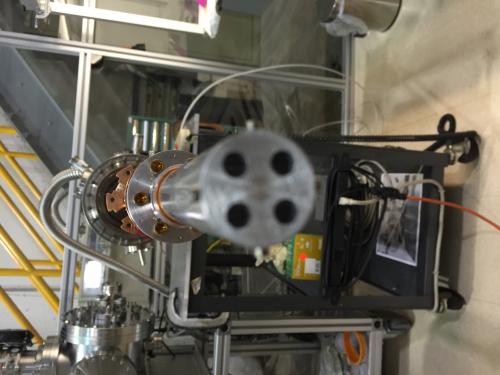

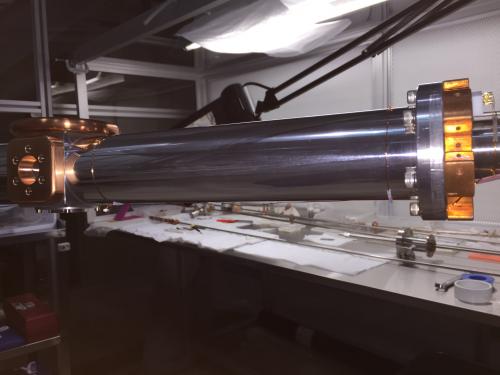

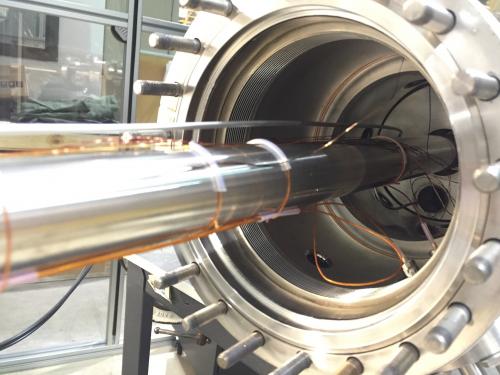

Cryostat wired up to and got ready for installation.

Feb 29, 2016:

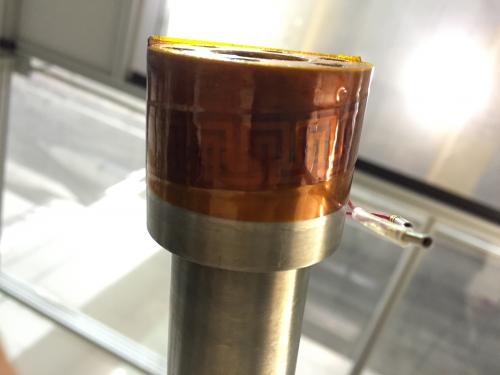

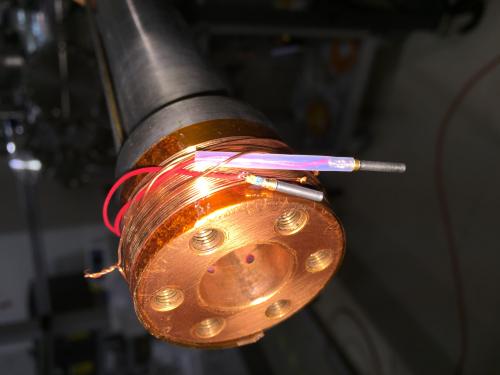

A number of attempts to fix the leak was unsuccessful. Two type of soft solder, Certanium 34C and UTP 570, were used and both were not helping. After each time, cryostat was cleaned to a workable stage.

May 5,2016

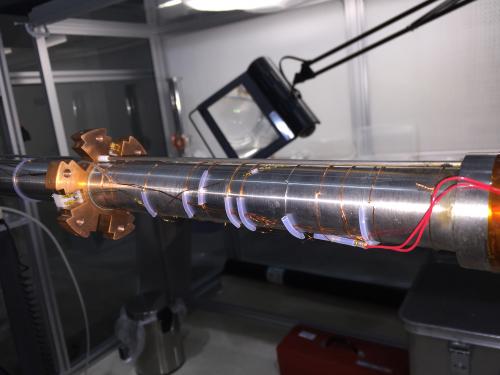

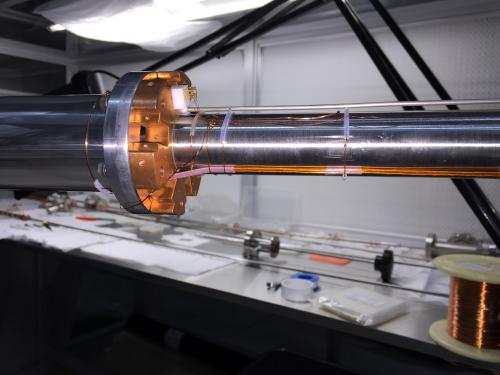

Cryo Industries Inc, recommended Duzall flux for low temperature soldering. So, this flux was ordered in march 2016 (Triumf PO: 1012280) and was tested April 26. Most of the soft solder were removed and Certainum 34C with Duzall were used. Cold test with liquid helium was fine until it came back to room temperature, and then started leaking. apparently, it failed after one thermal cycle.

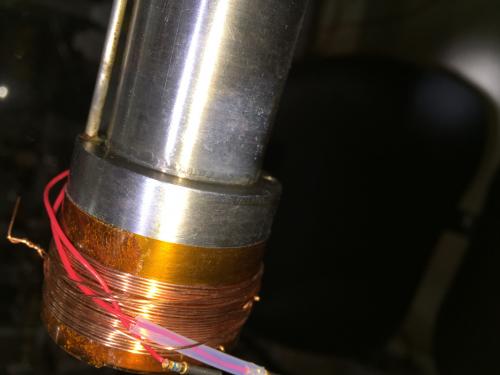

Second attempt with the same soldering material was done on May 3rd. This time using triangle file, all the residual of last soldering was removed by going deeper in the joint.

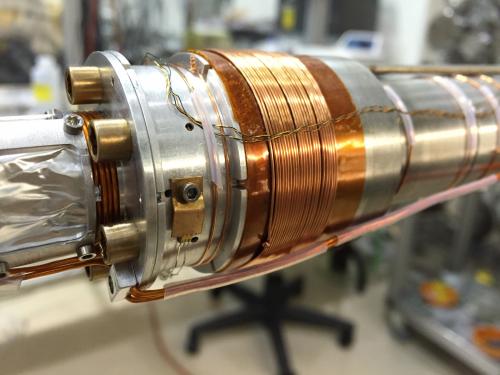

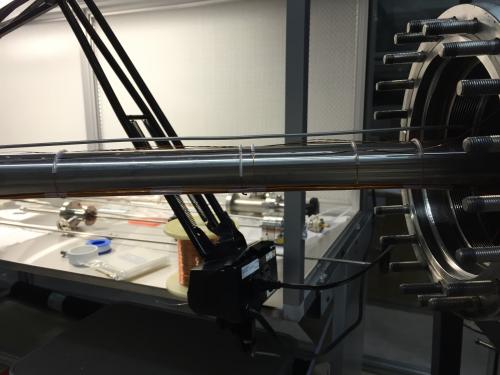

cold helium test started May 4 and continued until My 7. During this, three times complete cycles were completed and leak rate was less than 10-9 torr.lit/sec during the test.