Maintenance for OLP-18

Date:

Tuesday, November 24, 2015

Synopsis:

Repair on Pump

Equipment/Beam Line:

Description:

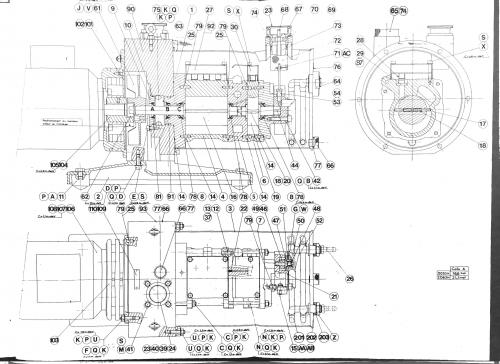

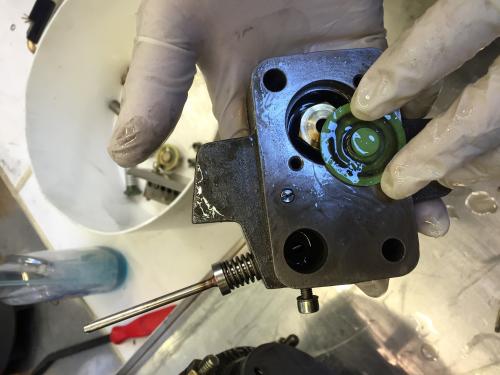

Pump's functionality dropped dramatically due to highe tempratue (more than 70C on the body) operation, and pump stopped working. Pump was taken apart, front plate and rear flange were scratched because of some bebries stuck to the rotors! Both flanged were sent to machine shop(by Tim) and using surface grinder, plates got resurfaaced.

End faces of HP and LP rotors' debbries were cleaned (by Deepak).

Pump was assembled and ran for 175 and the oil was changed (alcatel A111, 7.2 lit). There were some small metal particles and few brush strands.